- Company

- Products

- HERMES OREX – Digital Shelf Analyticse-Commerce Analytics for Brands & Retailers

- HERMES IRIS – AI Image RecognitionProduct Shelf Recognition Automation in Retail Execution

- HERMES Retail Execution & MerchandisingTrade-Marketing Software

- HERMES SFASFA Software for Pre-Sales | Van-sales Agents

- HERMES B2BB2B platform for manufacturers and distributors

- HERMES CRMCRM Software for Sales Agents

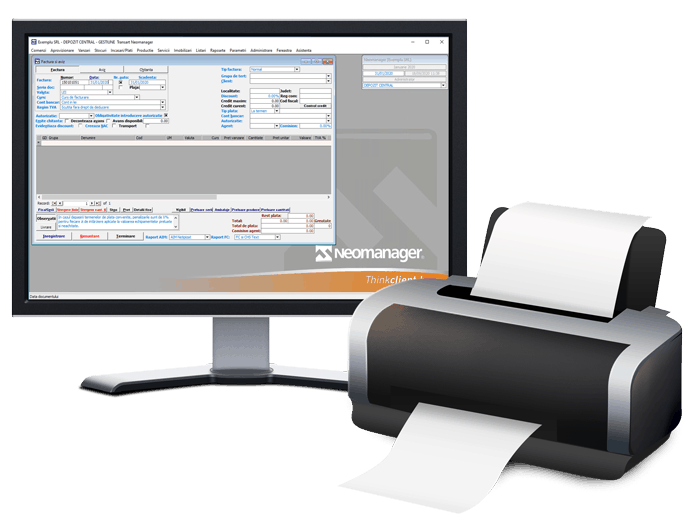

- B-Org ERP SystemERP Software - Enterprise Resource Planning

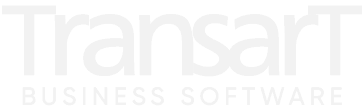

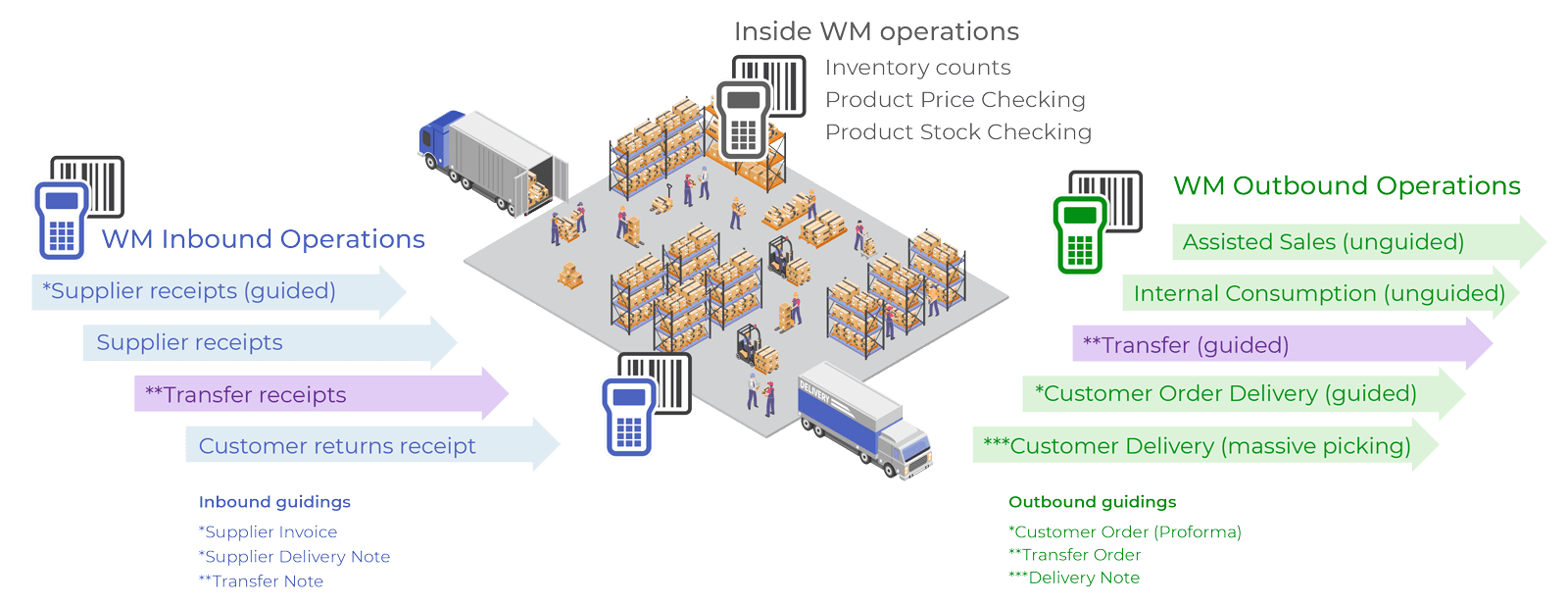

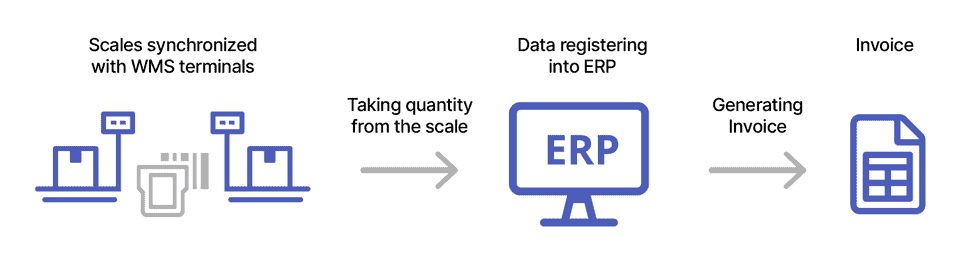

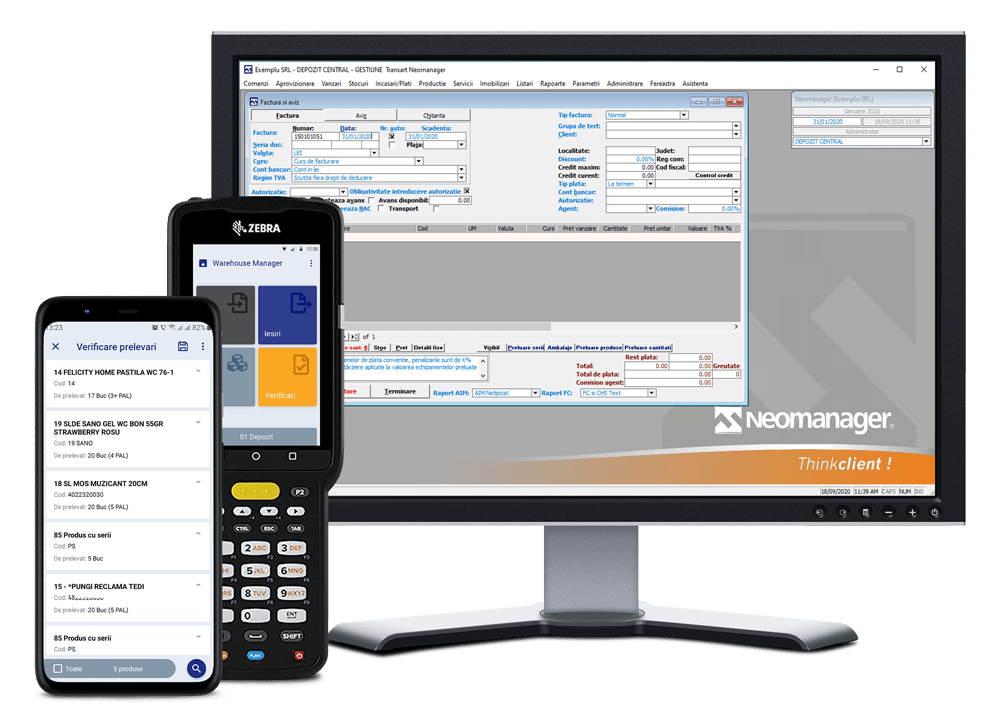

- Warehouse Manager WMSWarehouse Management System Software

- BI AdviserBusiness Intelligence Tool powered by Qlik

- Cortex DSiMDemand Signal Management System

- Solutions

- CRM Software for Consultative Selling TeamsHERMES CRM Romania – Customer Relationship Management

- Transart ERP integrates EDIElectronic Data Interchange in Transart ERP

- e-Shop / Online store B2C e-Commerce online store integrated with ERP

- Payroll programSoftware for Salary, Timesheets, Awards, Deductions.

- Inventory ManagementStock Inventory Management Software

- Business Intelligence ProjectsPower BI, Qlik and Tableau BI projects

- Customers

- Careers

- Blog

- Contact

- Company

- Products

- HERMES OREX – Digital Shelf Analyticse-Commerce Analytics for Brands & Retailers

- HERMES IRIS – AI Image RecognitionProduct Shelf Recognition Automation in Retail Execution

- HERMES Retail Execution & MerchandisingTrade-Marketing Software

- HERMES SFASFA Software for Pre-Sales | Van-sales Agents

- HERMES B2BB2B platform for manufacturers and distributors

- HERMES CRMCRM Software for Sales Agents

- B-Org ERP SystemERP Software - Enterprise Resource Planning

- Warehouse Manager WMSWarehouse Management System Software

- BI AdviserBusiness Intelligence Tool powered by Qlik

- Cortex DSiMDemand Signal Management System

- Solutions

- CRM Software for Consultative Selling TeamsHERMES CRM Romania – Customer Relationship Management

- Transart ERP integrates EDIElectronic Data Interchange in Transart ERP

- e-Shop / Online store B2C e-Commerce online store integrated with ERP

- Payroll programSoftware for Salary, Timesheets, Awards, Deductions.

- Inventory ManagementStock Inventory Management Software

- Business Intelligence ProjectsPower BI, Qlik and Tableau BI projects

- Customers

- Careers

- Blog

- Contact